The Virtual Foundry

Brad Woods

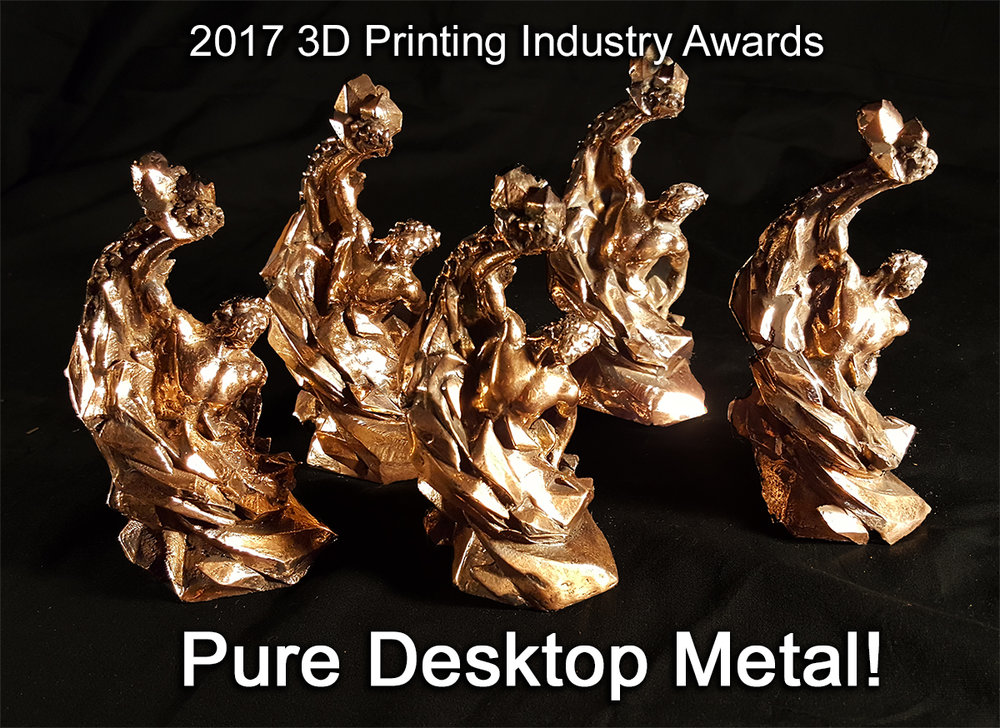

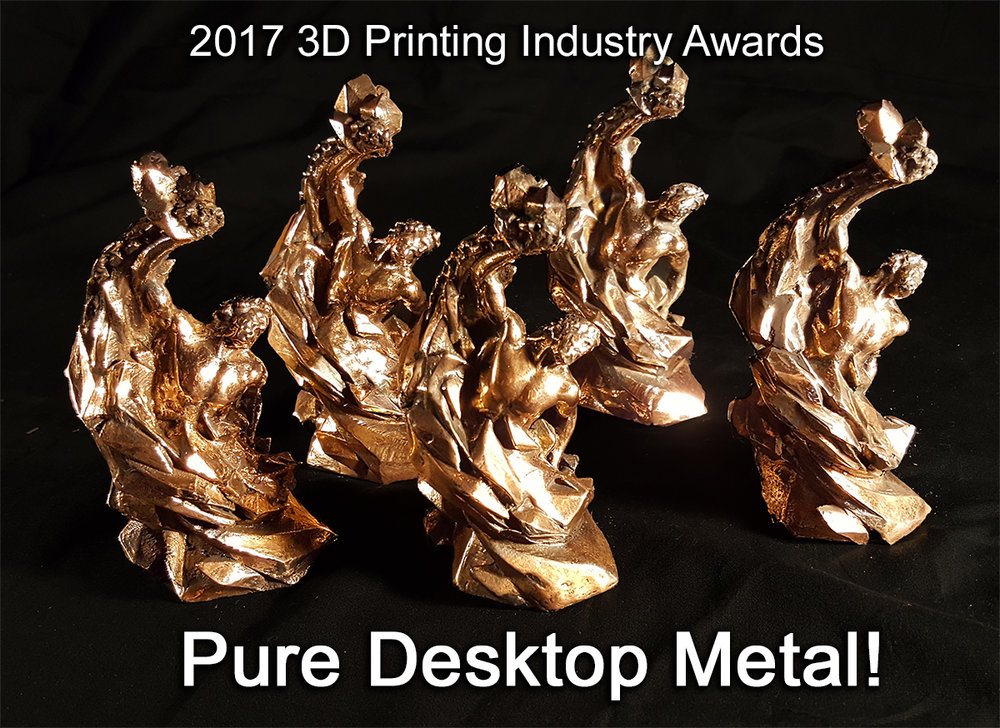

What is The Virtual Foundry? Essentially it's the quest to create high quality metal sculpture, jewelry and anything you can print, without requiring a complete, high-end, metals studio. This quest actually started well before 3d printing became a viable option earlier versions relied on combinations of cold casting and electroforming. Using these techniques we were able to create some striking copper objects. When 3d printing came into our lives, our first thought was that if it can't print metal, it has relatively little value. So began our 3 year quest to develop a product that would let any desktop 3d printer create pure metal output. After some early successes with high levels of metal infusion, we were able to produce about 20 pounds of what we now call Filamet™. This was enough to print some prototypes and develop a proof of concept. From here we looked to Crowdfunding as a way of bringing this development to market. Last year we did a successful Kickstarter campaign, raising about 135% of our target funding goal. This put our move from prototype to production into motion. Our early intent was to contract out manufacturing. After a series of meetings we concluded that we were not going to be able to find a vendor willing to put our secret recipe of exotic materials through their multi-million dollar plastics equipment. After this conclusion we set out to design our own system. We bought a 40 horsepower single screw extruder. Since there was really no product like this on the market, existing handling equipment just wasn't quite up to the job. Over the year following our Kickstarter we designed and custom built all of our own processing equipment. Being of the Maker generation, and Glenn being a highly skilled machinist (and Certified Master Metalsmith), we wound up with a set of custom machinery that can create product at a pace that exceeds our most aggressive estimates. For the nerds, all of our custom equipment is run by micro-controllers, some PIC's, mostly Arduino. So, today, we are manufacturing very large amounts of very high quality, high purity, 3d printing filament. We keep improving this number, but our current products are running at 88.8% metal. We consider the theoretical maximum metal content to be in the neighborhood of 92%. We hope to be running at this level by the end of this summer.

More Maker Info

http://www.thevirtualfoundry.com/More Event Info

More Project Info

http://www.thevirtualfoundry.com/

What inspired you to make this project?

Brad wanted to revolutionize 3d printing and make printing in metal available to any maker and not just those that could afford very expensive metal printers.